One of the two main objectives of the course is to further examine the hydraulic parameters used for pumping (NPSH, TDH, types of flow rate...) and how they come together in the form of network curves and pump curves. The second objective is to provide a detailed explanation of how pump motors work and to introduce the concepts of active, reactive and apparent power. After this course, the learner will be able to choose the right motor for a given pump.

The aim of the course is to explain why we carry out energy audits -- on pumping sites, tube wells or lift/disposal stations. It also explains how to carry out the various hydraulic and electrical measurements necessary.

This course focuses on the types and usefulness of energy performance indicators, as well as why we monitor and compare them over time. In particular, this course reviews the energy performance indicators used for pumps and for the various processes used in surface water and wastewater treatment plants.

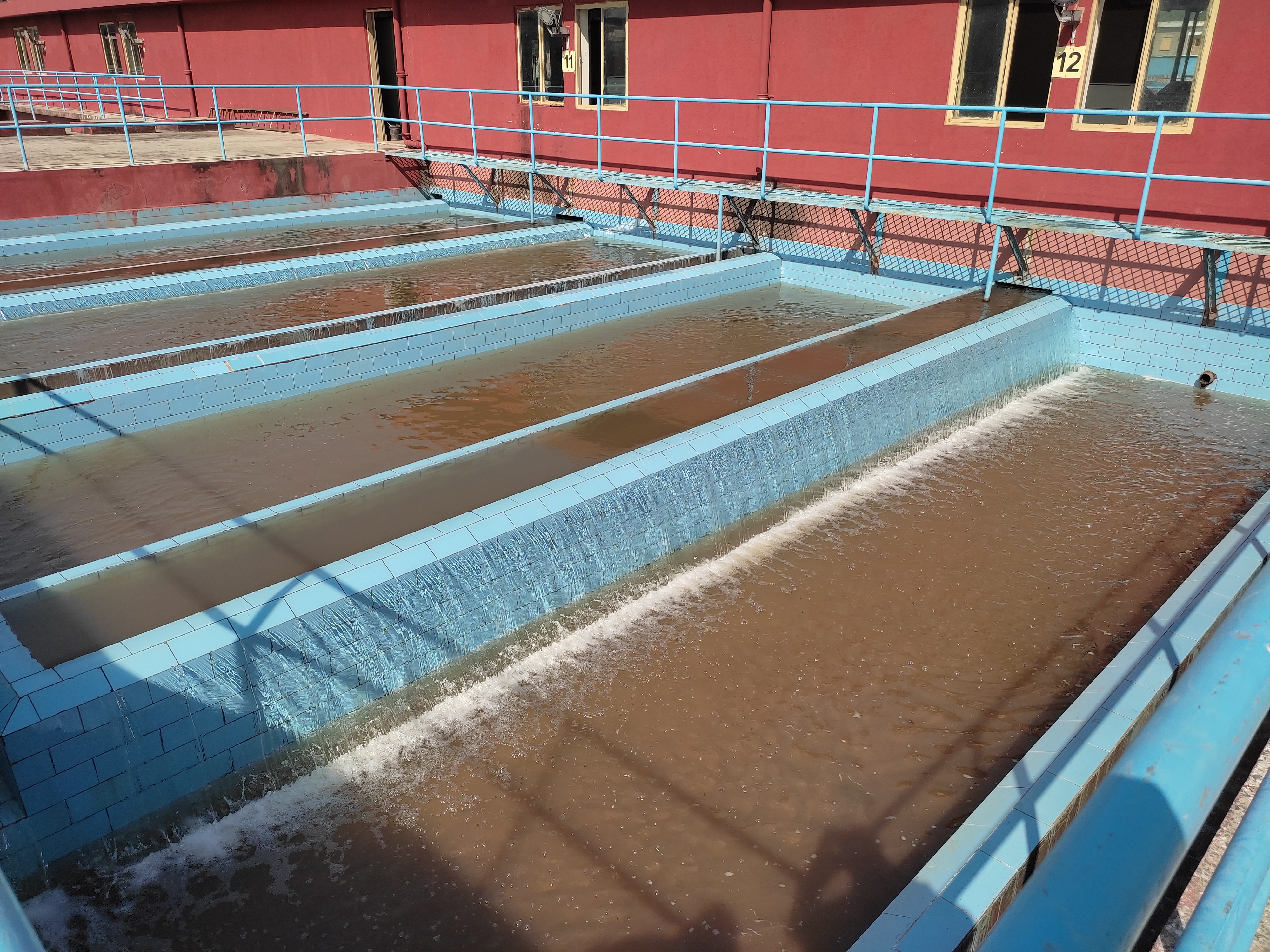

After this course, the learner will be able to carry out energy audits of surface water treatment plants, especially to estimate the energy consumed by the various processes. The second part of the course deals with recognising opportunities for energy optimisation, in particular on the main energy-consuming processes of the two types of plants. More specifically, these include the backwashing of filters for surface water treatment and activated sludge for wastewater treatment.